The lifespan of strapping is influenced by a variety of factors, making it difficult to provide an exact fixed duration.

Looking at the material's inherent properties, take polypropylene (PP) as an example. In an ideal indoor environment, it can maintain good performance for many years. Polypropylene has relatively good chemical stability. Under normal indoor temperature and humidity conditions and when protected from direct sunlight, the strapping will not easily undergo chemical changes, and its lifespan may reach 5-10 years or even longer. In such an environment, it can continuously and stably perform its binding function, used for securing general goods, such as the packaging of small electronic products, daily necessities, etc.

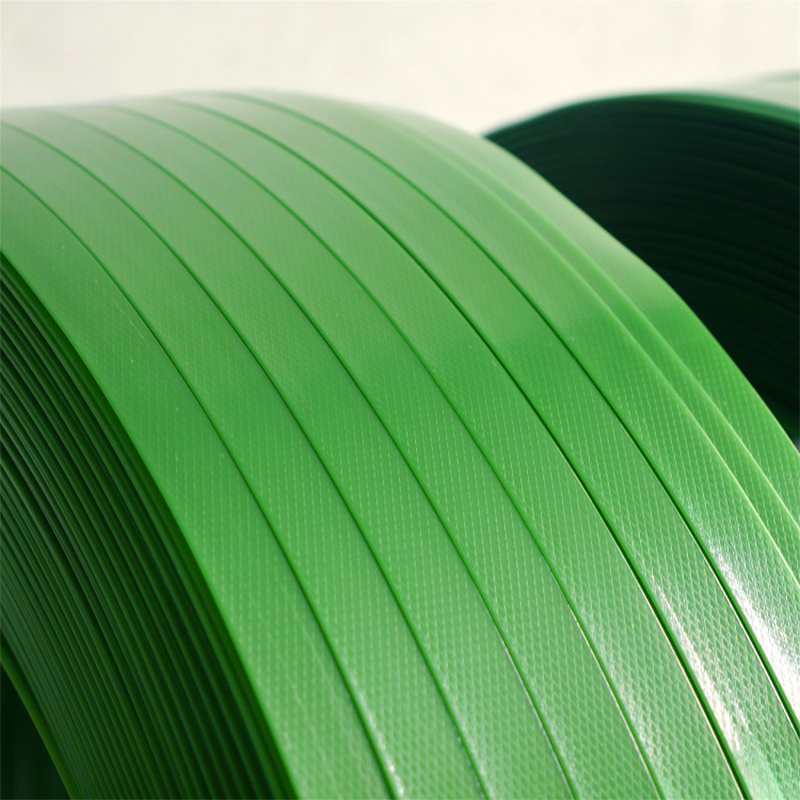

Polyester (PET) strapping, due to its higher strength and resistance to aging, often has a longer lifespan in suitable environments. Especially in situations where long-term storage is required, such as the packaging of large equipment and industrial materials, polyester strapping can resist the erosion of environmental factors, and its lifespan may reach around 10 years, or even exceed this time frame under certain conditions.

However, environmental factors have a significant impact on the lifespan of plastic strapping. In outdoor environments, ultraviolet (UV) rays from sunlight are a key factor in shortening the lifespan of strapping. UV rays can trigger photo-oxidative reactions in plastics, causing the strapping to age and become brittle. For polypropylene strapping, prolonged exposure to sunlight may result in noticeable aging in about 1-2 years, such as yellowing of color, reduced strength, and even breakage. Although polyester strapping has relatively stronger resistance to UV rays, it may also begin to experience performance decline after about 3-5 years of prolonged exposure to strong outdoor light.

Humidity is also an important factor. If strapping is kept in a high humidity environment for a long time or comes into direct contact with water, polypropylene strapping may undergo hydrolysis, causing its molecular chains to break and its strength to decrease. In this case, it may lose its effective binding function in a few months to about a year. Polyester strapping has slightly better tolerance in humid environments, but if soaked in water for a long time, it will also be damaged, and its lifespan will be greatly reduced.

Moreover, the load and usage frequency that the strapping bears also affect its lifespan. If it is frequently used to bind heavy goods and is often subjected to significant tensile forces, both polypropylene and polyester strapping will wear out and become fatigued more quickly, and their lifespan may be only half or even less than under normal conditions.